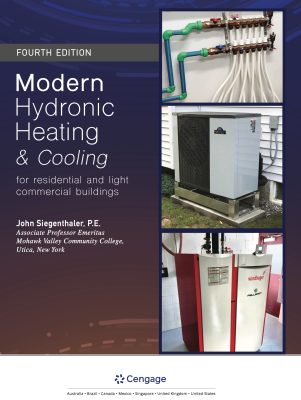

PP-R system is suitable for numerous applications

Contractors value additional services pipe manufacturers can provide such as professional, precise prefabrication. Photo courtesy of Aquatherm.

Earlier this year President Donald Trump signed an order imposing a 25% tariff on foreign steel and a 10% tariff on aluminum.

Steel prices can be volatile with or without tariffs, due to changing raw material costs, but the Section 232 investigation and subsequent 25% tariff has caused additional concern about the uncertainty of traditional piping systems.

“We have seen a lot of anxiety with many orders getting pulled forward or rushed,” says Jeff Morello, a pipe hub manager at national distributor Ferguson. Morello adds that many customers are seeking to “get ahead” of any potential price increases and supply shortages.

Morello believes the industry is just scratching the surface of understanding the total impact of the Section 232 tariffs.

“The goal was to negotiate a long-term arrangement for those countries,” he says. “But even those arrangements come with new conditions.”

Knowing the road ahead is uncertain, an increasing number of contractors have been open to discussing piping solutions that don’t just emphasize the reliability of the product but address the stability of pricing and offer a potentially favorable total installed cost.

“When we get involved early in the planning process we can assess which pipe is the right fit,” says Thomas Atkinson, fabrication manager at Ferguson’s Fulton, Mississippi, pipe hub. “We understand contractors are making a huge investment in pipe. Ferguson is just interested in finding the right solution for that job.”

Mark Bobrowski, senior mechanical engineer for preconstruction services at John E. Green Co., in Highland Park, Michigan, says rising prices may indeed provide an incentive for end users to consider alternative piping options.

“We have customers coming to us asking to learn more about the alternatives that are available to them and they’re receptive to new products,” he says. “Price changes should bring more attention to alternative products and make more people wonder what’s out there other than traditional materials.”

For example, John E. Green has successfully used Aquatherm, a polypropylene-random (PP-R) piping solution, in many projects over the last several years.

Bobrowski notes PP-R pipe is not subject to the tariffs and also is flexible in design, allowing it to be integrated as a hybrid approach with other pipe systems. Bobrowski adds PP-R is suitable for a wide range of applications, including heating and cooling distribution, geothermal, condenser water, potable water systems, graywater and numerous industrial applications.

“Contractors are always interested in bringing the most value to their end customer and many times that means passing on savings to them,” Ferguson’s Atkinson says. “I think it’s easier for contractors to take the leap of faith on the labor savings and pass on the other benefits of PP-R to their customers.”

Price stability and fab services

Aquatherm officials note the company’s PP-R pipe hasn’t had any significant shift in pricing since 2008. PP-R, which is connected by heat fusion, also offers a potential total installed cost advantage in the form of reduced welding times and no need for a flame watch, as well as an anticipated life span of 60 years.

Jamie Hassett, president, Demand Mechanical out of Nashville, Tennessee, points out cost is usually the No. 1 concern for many building owners and managers, especially for mechanical work.

Atkinson notes another key is the availability of design and fabrication services with PP-R pipe, which Aquatherm offers at its North American headquarters in Utah, as well as fusion and installation training at jobsite and partner locations.

“Fusing the pipe in-house makes it really easy to bolt together on the jobsite,” he points out.

Bob Harvey, owner of Harvey’s Plumbing and Heating in Bozeman, Montana, says fabrication saves him a tremendous amount of time and labor.

“Everything is switching in the direction of pre-fabrication,” he states. “That’s the direction I’m going: BIM it, fabricate it, build it.”

Morello says contractors, designers, facility managers and building owners who all are looking to keep their competitive edge would be well-advised to explore PP-R pipe.

“In times like these, my best advice for contractors is to be proactive,” he says. “If you have something you know is needed, get ahead of it and secure it.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!