Supply House Times Profile Q&A

Supply House Times Profile: JJM Alkaline Technologies

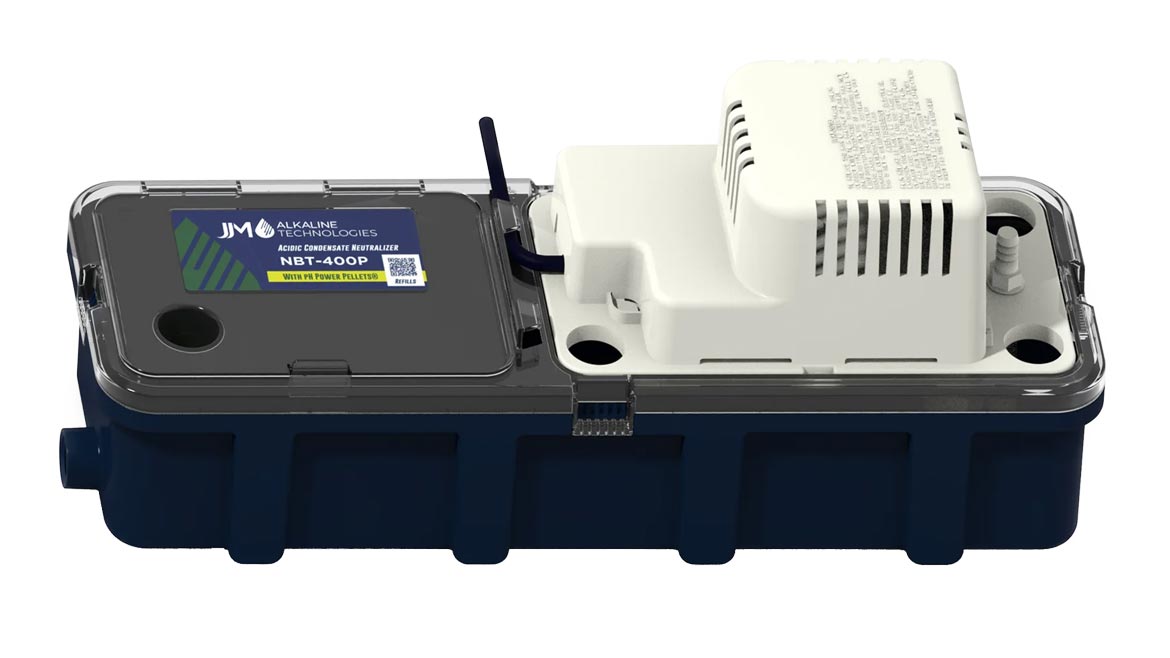

Condensate neutralizer manufacturer shares trends in high efficient appliance market.

Image Source: M-Production / iStock / Getty Images Plus via Getty Images

JJM Alkaline Technologies was founded in 2005 by George Carney. Carney was a career boiler salesman who saw the need in the market to safely and effectively treat acidic condensate when condensing technology was first gaining traction. Carney and his wife started the company out of their garage and today, JJM® is a leading designer and manufacturer of condensate neutralizers for the heating and plumbing industries. The company built the first one.

Supply House Times sat down with Kyle T. Emmons, founder of JJM Alkaline to hear more about the company and its goals.

SHT: How has the company evolved since its founding in 2005?

KE: From its modest beginnings, the company’s innovative condensate neutralizer solutions quickly gained traction in the industry. JJM® reached an inflection point in 2010 and George and Denise committed to leading the business full-time and expanded into a larger facility to increase capacity. Since then, JJM® has continued to grow its team, invest in its processes, expand into a larger facility, and launch new product offerings to meet market needs.

SHT: What are your primary market sectors? How do JJM Alkaline products fill a need in today’s marketplace?

KE: JJM condensate neutralizers are reliable, purpose-built solutions that safely treat the acidic condensate produced by today’s gas-fired, high-efficiency heating appliances (such as boilers, furnaces and hot water heaters) in both the residential and commercial HVAC and plumbing sectors.

SHT: Why are condensate neutralizers important? Why is the need for them growing in today’s marketplace?

KE: A condensate neutralizer acts like a filtration device with an engineered housing filled with neutralizing media, such as magnesium hydroxide, which raises the pH level of the acidic condensate to a safe level before it’s discharged into the plumbing and wastewater systems. This in turn helps prevent potential damage to facilities or the environment. Left untreated, this acidic condensate can corrode plumbing, concrete foundations, floor drains, septic systems and other wastewater infrastructure. A critical complement on every condensing installation, these filtration devices ensure that high-efficiency heating systems operate safely, achieve code compliance and ultimately fulfill their environmental promise.

Government energy standards are requiring manufacturers of heating appliances to use condensing technology. In fact, by 2029, all gas-fired appliances will use condensing technology so the need for condensate neutralizers will continue to grow significantly.

Installations where a small footprint is warranted. The NB-Series is capable of handling installations with multiple heating appliances. Image courtesy of JJM Alkaline Technologies

The V-Series is the vertical mount solution from JJM that is ideal for single and multi-unit residential installations where space is limited. Vertical wall mounted. Image courtesy of JJM Alkaline Technologies

SHT: What should contractors and homeowners know about neutralizers?

KE: Unlike air conditioning condensate, acidic condensate from condensing heating appliances is corrosive because it includes various acids from the combustion process. A typical residential, gas-fired, high-efficiency heating appliance will produce approximately 2 gallons per hour of acidic condensate. Across the U.S., it is estimated that nearly 9 billion gallons of acidic condensate are produced by condensing appliances every year. That’s a lot of potential damage to property and the environment. Condensate neutralizers are the solution to this overlooked or misunderstood problem. These purpose-built devices protect facilities and wastewater infrastructure from potential damage. Plumbing regulations prohibit the discharge of such corrosive wastes into the wastewater system so these solutions also ensure code compliance. Similarly, condensate neutralizers prevent the destruction of septic systems given that untreated acidic condensate will destroy beneficial bacteria. Plus, neutralizers safeguard the surrounding environment and groundwater. Contractors and homeowners can trust JJM® condensate neutralizers to ensure today’s high-efficiency, gas-fired heating appliances fulfill their environmental promise.

SHT: Describe your relationship with distributors and reps? What is your go to market strategy?

KE: JJM® products are sold via leading wholesale distributors of heating and plumbing equipment throughout the United States and Canada. JJM® is a big supporter of the wholesale channel and works with manufacturer’s representatives across the country to support our distributors and contractors in their local markets. JJM® is a member of HARDI and ASA, among many other industry organizations.

SHT: What are the top three trends you see in high efficiency appliances and plumbing today?

KE: More and more gas appliances are adopting and introducing condensing models, such as furnaces. Gas tankless water heaters are taking more and more share. Service technicians are more attentive to recurring service opportunities from annual equipment maintenance.

SHT: What are your short and long-term goals for the company?

KE: In the short term, JJM expects to grow over 3x. Looking long term, JJM strives to become the dominant category leader and we expect the company to be synonymous with condensate neutralizers.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.jpg?height=200&t=1652414487&width=200)