Why didn’t my fire sprinkler system work?

A comprehensive plan of attack can prevent physical and financial disaster.

If fire water supply is not available at the minimum pressure and volume for which the system is designed, one has to hope for the best and wait for the fire department to arrive. During a field investigation of a building up for an expansion, I normally check the existing life safety systems to verify what I have to work with. Verifying fire alarm status and fire water flow data is part of that investigation.

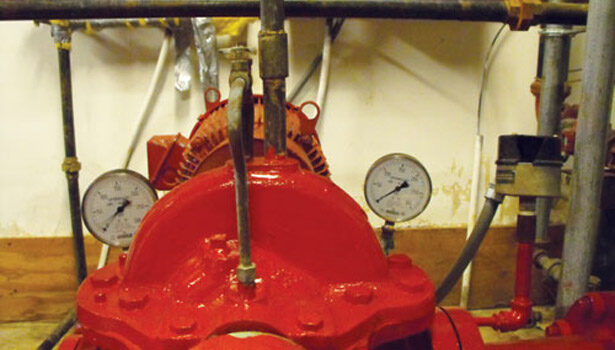

One recent visit involved checking exterior hydrant status and taking flow data. However, the hydrant on the building fire water main seized. I checked inlet and outlet pressures to the fire pump inside the building. The static pressure was 70 psi. I then began opening valves to the exterior pump test outlet to trigger the fire pump operation. The fire pump kicked on, the pump inlet pressure gauge went to zero and the pump outlet pressure was about 10 psi.

This pump was installed to operate at a minimum inlet pressure of 20 psi with a minimum flow of at least 450 gpm. There was no way it was going to do that. I began normal shutdown and reset of the pump and valves. Alarms went off in my head about why the pressure dropped to zero.

Low fire flow and pressure causes

What causes are at the root of low fire water flow and pressure? There may have been insufficient water volume to support the number of sprinklers activated during the fire event or during a site systems test. The building owner might say: “I have a fire pump. Why didn’t that work?” A fire pump doesn’t create volume (flow), it increases pressure. If there is pressure but no flow available, the fire pump will pull what little water is there and then begin to fail and overheat. Low water volume from the fire water supply main to the building could mean the main has a blockage or a partially closed valve.

The fun at this point is trying to find out who is responsible for regular maintenance and testing of the fire mains outside the building and who is responsible for suppression system maintenance and testing inside the building. Regular hydrant flow test records at and around the site also will give clues as to where the problem might exist depending on where the hydrants connect to the building fire main.

There is no way to know if the fire main is impaired if it is supplying the building separately from the domestic supply and the fire flow is not tested regularly as required. Unfortunately, a fire event may be the only thing to draw attention to the problem. Then the question comes up, “Why didn’t my fire sprinkler system work?”

We have a problem

The hard part for a fire protection engineer is verifying the building sprinkler systems do not work and then explaining this to the building representatives. This has to be handled delicately as the FPE’s first instinct will be to pull the nearest manual fire box, trigger the fire alarm and clear the building until the required life safety systems are back online. However, the facility is most likely fitted with a functioning fire alarm system, which should sound an alarm upon detection of heat or smoke.

Further, the facility should have the required means of egress for emergency evacuation. These are additional safeguards intended to operate in conjunction with a fire sprinkler system, but still support a significant level of safety on their own. The FPE will notify the building security, facilities engineer and site manager of the life safety system impairment. Those discussions lead to other individuals who should be notified.

What are the solutions?

Simpler systems are less likely to fail. If a municipality allows a combined domestic and fire supply main to a building, I recommend it. There may not be as high a demand for normal domestic use as there is for a fire suppression system, but people will speak up if their showers and toilets don’t have enough pressure. In that case, impairments to the supply water are investigated.

Running separate domestic and fire mains outside the building makes sense if the municipality requires a detector check on the fire main — only metering the domestic supply at a property line vault. The problem here is that detector check valves on fire mains cause pressure loss in the line inherent to their design. If a valve fails on the fire water main, no one knows until there is a fire event or a system test.

The plan of action in the above scenario was to have the contractor who does regular maintenance and testing of the site hydrants test and investigate the system impairment. Tentative future plans include replacement of the 30-year-old, 6-in. fire main and detector check valve with an 8-in. fire main and detector check valve. Regular required maintenance, testing and recordkeeping could help prevent problems such as this from getting worse at similar sites.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!