Committee educates our industry

When I was in high school and college, I worked at a now-defunct department store with a significant warehouse component to it.

Needless to say, while in said warehouse we didn’t take safety too seriously. I saw workers jump from the top of a wire storage rack to the one in the next aisle like they were competing in the long jump at the Summer Olympics. Employees rode the conveyor belt and even locked a new hire in the trash compactor as a joke.

I got in on the act as well. My specialty was throwing fluorescent lighting tubes against the back of the trash compactor and watching with delight as they exploded — all sans protective eyewear.

All that foolish behavior could have immediately turned tragic if someone had fallen off one of those bins to the concrete floor or if broken lighting tube particles became lodged in my eye. I don’t even want to think what could have happened if that trash compactor malfunctioned while a “joke” was being played.

Safety in the workplace is no joking matter.

And in an industry such as ours that features manufacturing, warehouse and shipping/receiving elements, observing proper safety protocols is even more important.

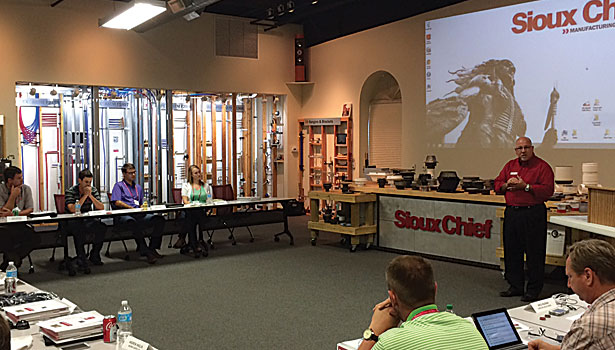

Enter the American Supply Association’s Safety Committee. This group, comprised of representatives from ASA member manufacturer and distributor companies, is doing all it can and then some to make sure companies and individuals operate at the highest levels when it comes to workplace safety.

NIBCO’s Ricky Bryant is one of three founding members of the committee along with LaCrosse, Wis.-based First Supply’s Mary Prahler. Bryant is retiring as committee chair at year’s end and will hand the reins over to Prahler. Both are passionate about workplace safety. That was evident from the video interview I conducted with them at NetworkASA 2014 in Las Vegas (available at http://www.supplyht.com/videos).

In its six short years of existence, the committee has made major strides in its mission to best prepare ASA member companies and their employees on the safety front. The committee sponsors educational webinars, produces Web-based Tool Box Talks on a variety of safety-related subjects (visit

http://www.asa.net/safety-resourcesto access the Tool Box Talks) and has established a strong relationship with OSHA. It also assembles the informative Eye on Safety column in Supply House Times, where recent topics have included sudden cardiac arrest, dealing with insects and how to prepare for extreme hot and cold weather.

The Safety Committee recently issued its third annual safety awards and Bryant notes the committee received more nominations than ever this year. Ardente Supply, MKS Pipe & Valve, American Pipe & Supply and First Supply were distributor winners this year, while Prier and NIBCO earned manufacturer safety honors.

Bryant says ASA member companies are taking the safety ball and running with it. “There are companies that will have 15-20 minute meetings with their workers and train them on something safety-related,” he says. “Some are doing this once a week and some once a month. It’s encouraging.”

Prahler adds the primary focus of the committee is to constantly keep the topic of safety on the front burner throughout companies. “Mistakes and bad decisions are bound to happen,” she says. “It doesn’t take much to create havoc. If people are constantly reminded about safety, fewer accidents are going to happen.”

And as Bryant explains, less workplace mishaps can have a far-reaching impact on a company. “Accidents affect the bottom line when you are talking about things such as workers’ compensation and lost productivity,” he says. “When people aren’t working and productivity suffers, it adds up very quickly. If people feel like they are working in a safe environment, they are happier and more productive.”

Prahler has some easy advice for companies looking to strengthen their safety measures. “Form a safety committee within your company,” she says. “The OSHA website has a treasure-trove of helpful information. Get involved with safety training. Successful companies have successful safety programs. The two go hand-in-hand.”

Bryant adds: “My goal every night is to have every employee go home in the same condition they came to work in. Make your workplace safe. People are your most valuable commodity.”

HELPFUL LINKS:

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!